Research

Home > Research > ITO laboratory

Research fields/Keywords:polymer processing, especially precision injection molding, micro and nano devices, structure and physical properties of polymeric materials, including polymer composites, alloys and blends

Professor Hiroshi ITO

Professor Hiroshi ITO

A great number of plastic products are in use all around us. For example, plastics are widely used in automobile bumpers and motorcycle bodies; sporting goods; home appliances and information systems etc. Plastic products are also used for mobile phone covers, backlight, connectors, optical films of liquid crystal displays, reflecting films etc.

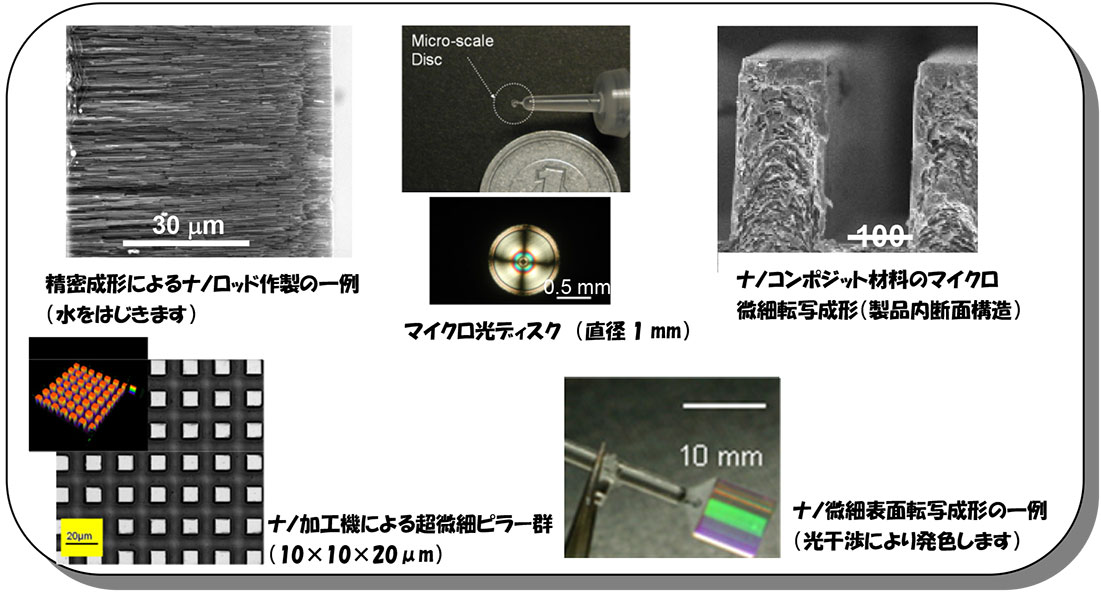

Recently, there has been demand for value addition and greater functionality in polymer products. One approach to address this demand that has been gaining attention is the use of microscale and nanoscale ultrafine precision processing. As the basic components fabricated using these processing technologies find wide use in medicine, telecommunications, robotics etc., there is active ongoing research on precision processing at the micro and nanoscales.

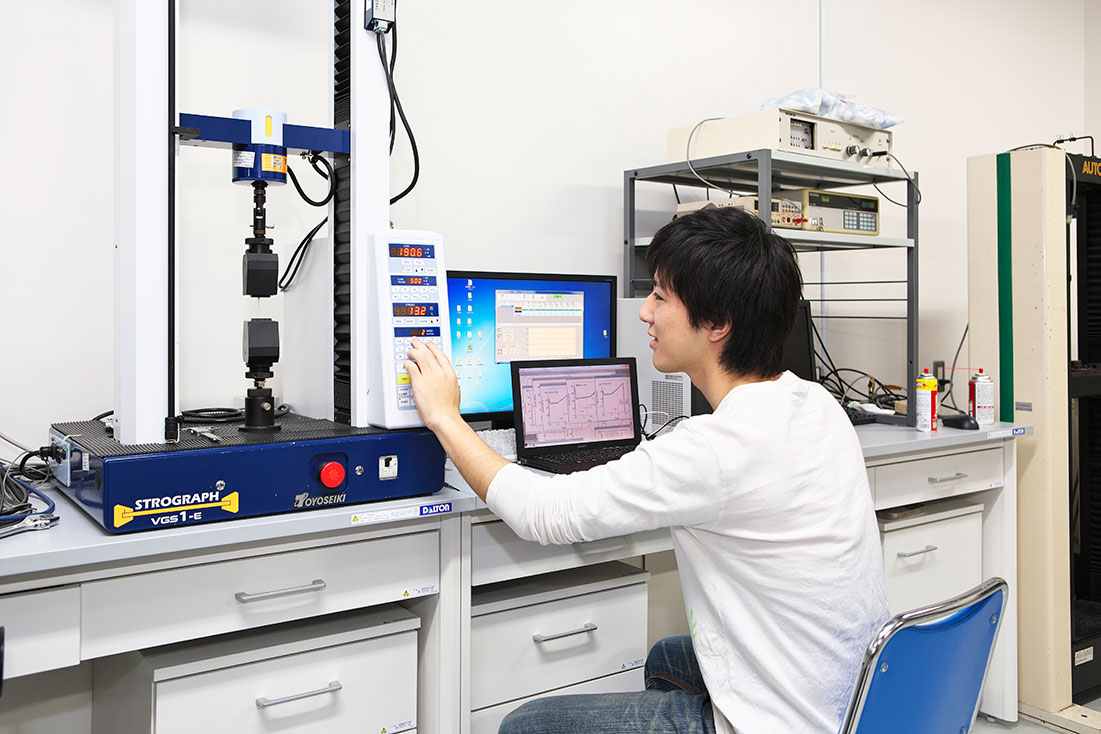

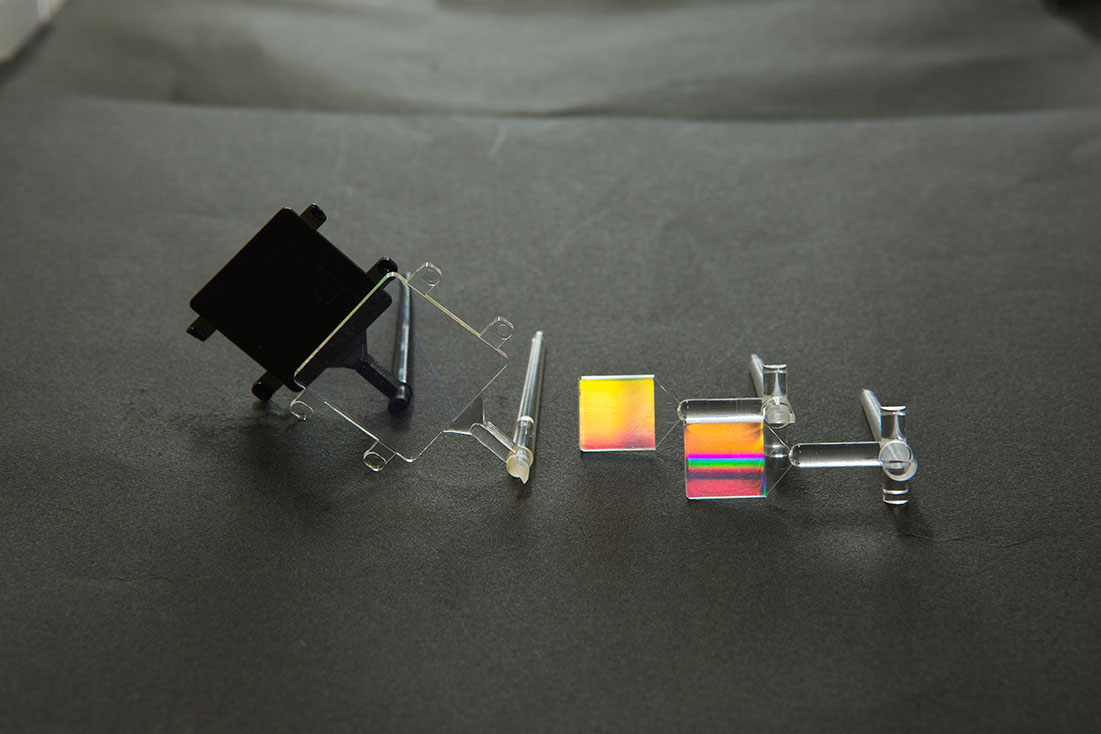

By focusing on microscale and nanoscale polymer processing, we are investigating ultrathin molding, micro and nano surface patterning, microscale processing, ultraprecision processing, functional composites processing etc. In addition, we are actively developing high value-added components with high functionality such as micro and nanoscale plastic parts, optical elements etc. We will clarify various processing characteristics, structure creation, and novel physical properties created by combining the top-down approach of conventional processing with a bottom-up approach focusing on autolysis, self-organization, crystallization, and molecular orientation etc. of the polymeric materials. Polymer devices are also studied. We are actively collaborating with partners in several industries including automobile, precision machining, optical devices, manufacturing and processing, chemical etc.