Research

Home > Research > TAKAYAMA laboratory

Research fields/Keywords:polymer composites, mechanical properties, material design, extrusion, injection molding, prediction of mechanical properties

Associate Professor Tetsuo TAKAYAMA

Associate Professor Tetsuo TAKAYAMA

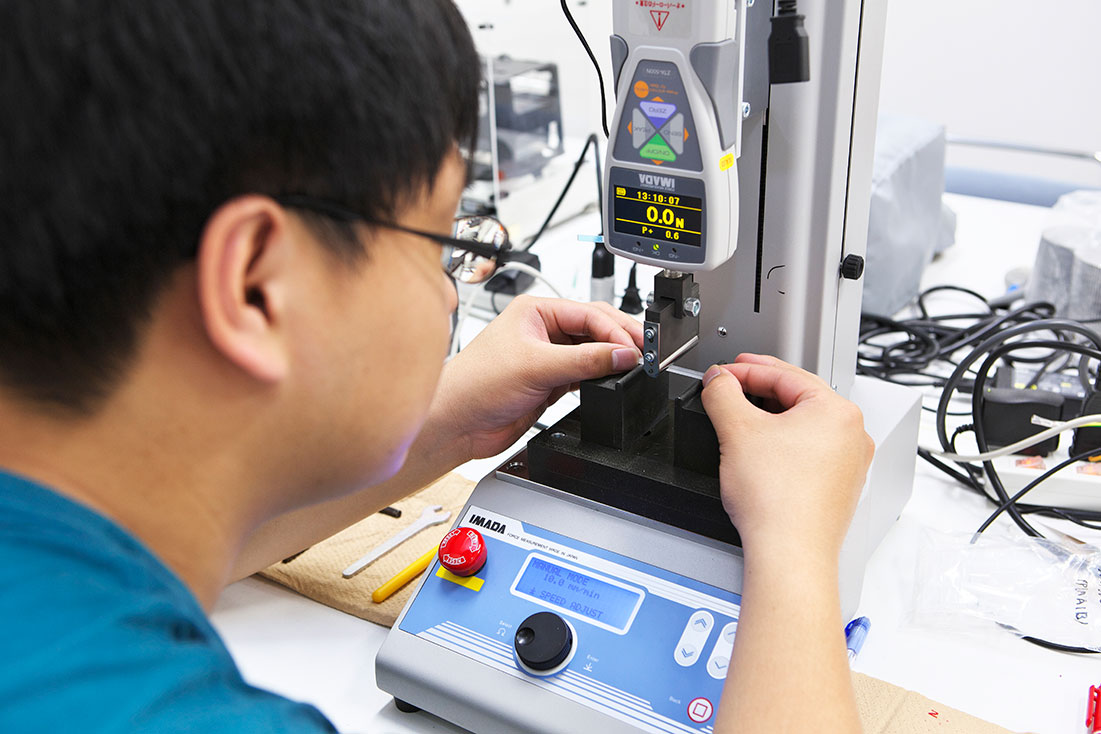

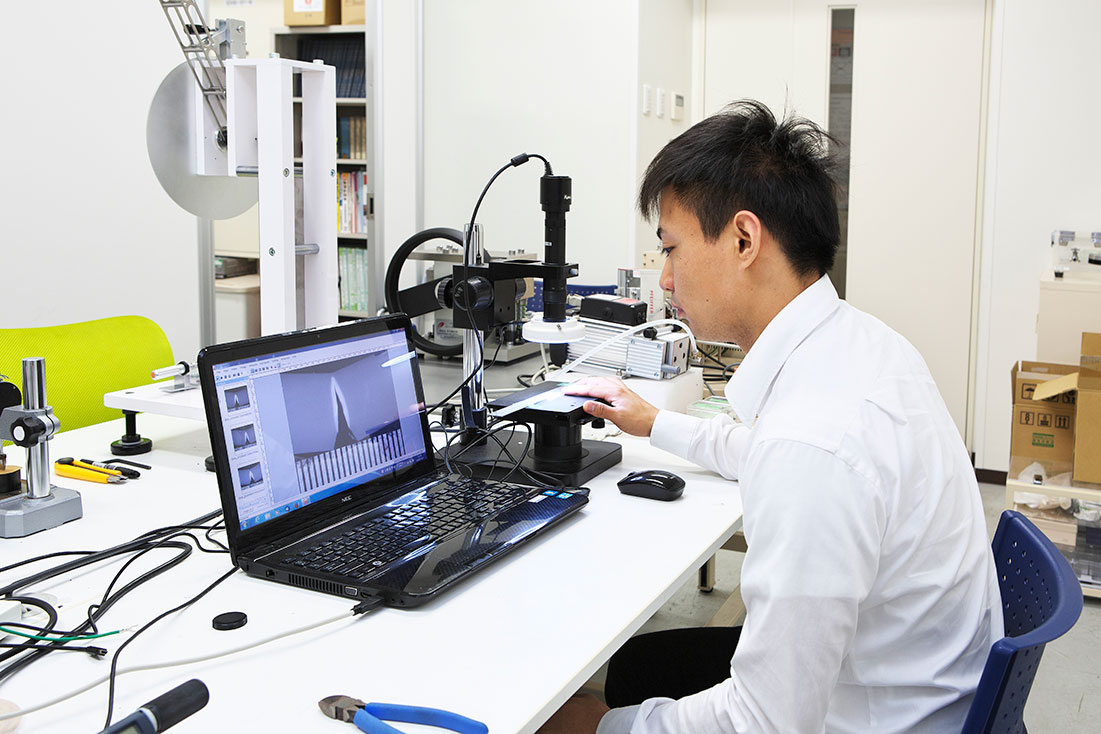

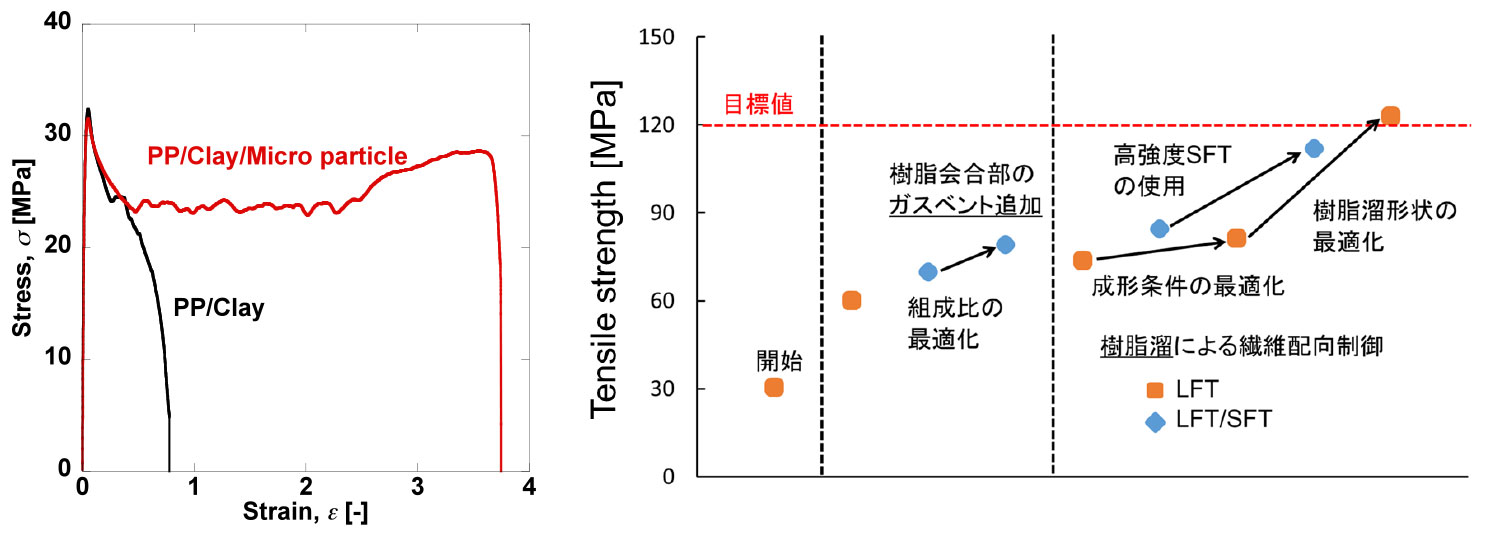

Polymer composites are combinations of polymeric materials with other materials. As they possess the lightness, chemical resistance and processability of polymers and the excellent mechanical properties of metals and ceramics, they are utilized in medical treatments, automobiles, consumer electronics, aerospace etc. Because the physical property requirements becoming more exacting with each passing day and the consequent severe time limitations, there is great demand for achieving excellent performance in a short time through material design.

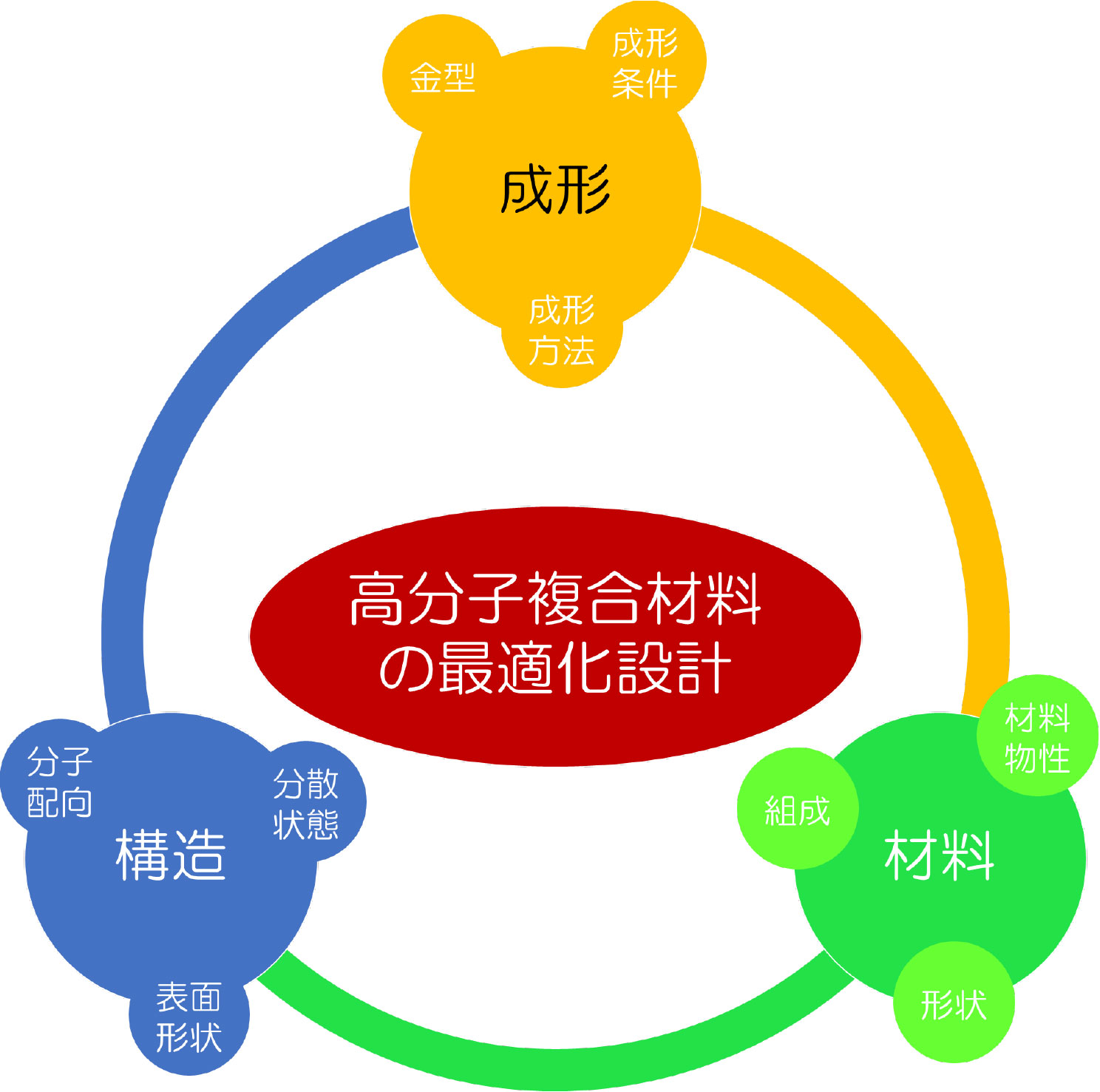

The physical properties of polymer composites vary with the shape, size and size distribution, and the quantity of material used in preparing the composite. Moreover, physical properties also depend on the processing technique and the processing conditions. Interpretation of the physical properties and their prediction is rather difficult and as a matter of fact, still being actively investigated. In other words, it is necessary to carefully consider and combine all three aspects: materials, structure and processing.

Our laboratory aspires to contribute to the development of the polymeric composite materials industry by proposing guidelines for and a theory of materials design. Towards this end, we carefully investigate the three aspects that determine physical properties: materials, structure and processing. (Excerpt from HP)